Charcoal/Coal Briquette Extruder Machine for Barbecue Charcoal/Coal Press Machine

Basic Info

| Model NO. | SL-140; SL-160; SL-180 |

| Pressing Mode | Extrude |

| Product Shape | Customization |

| Motor Type | Customization |

| Condition | New |

| Application | Heating Cooking BBQ |

| Final Shapes | Customized:Hexagon,Round ,Finger Shape and So on |

| Pressure | Roller Pressure |

| Warranty | 1 Year |

| Capacity | 500kg-1000kg |

| Certification | ISO SGS |

| Transport Package | Plywood |

| Specification | 2030*1260*1080 mm;2200*1260*1080 mm;2320*1600*1150 |

| Trademark | SL |

| Origin | China |

| Production Capacity | 500-1000 Kg/H |

Product Description

charcoal briquette extruder making machine

Product Description:

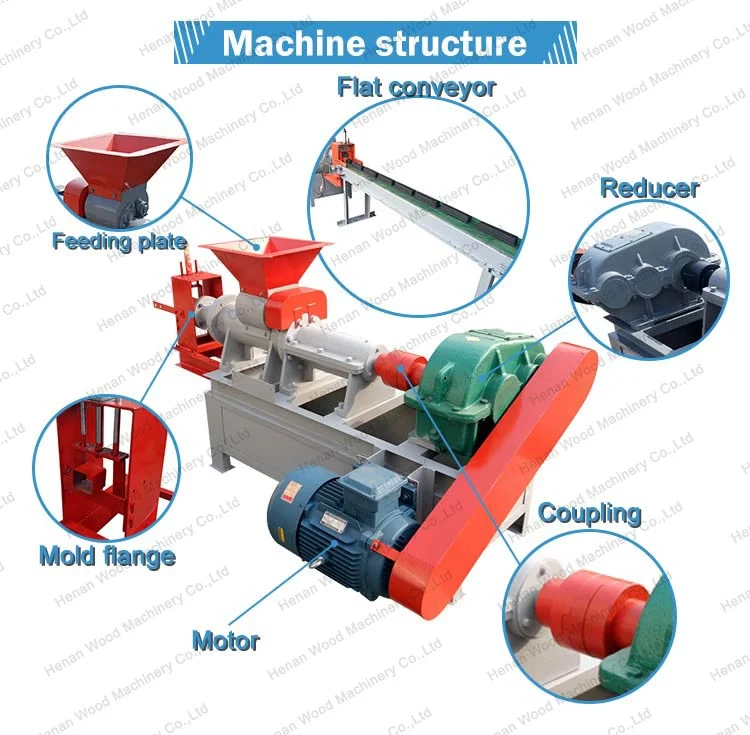

1.Charcoal/coal briquette machine can produce the charcoal/coal briquette,the final charcoal can be used for the BBQ this machine have motor,v-belt,transmission machine,shaft,feeding inlet,propel screw,mould

2.It can produce different shape,change the mould is ok.The normal shape is hexagon shape ;the length is 10-12cm,diameter is about 5 cm.

3.Raw material"charcoal/coal powder;Cow dung;Grass powder;Oil residue.

Working process :

The motor drive the v-belt drives transmission machine and the shaft,the will drives the screw,screw push the material into the mould,then can produce the charcoal briquette.

Production details:

The normal size of the final charcoall briqutte: length is 10-12 cm,the diameter is 5cm;the length can be adjusted by the Infrared sensor probe,adjust the distance between the probe and the mold.

Spare parts:

This machine have two spare parts,screw and mould.

Technical parameters of the charcoal briquette extruder making machine

Model | Motor(kw) | Capacity (kg/h) | Weight(kg) | Dimension (mm) |

SL-140 | 11 | 500 | 650 | 2030*1260*1080 |

SL-160 | 15 | 600-800 | 720 | 2200*1260*1080 |

SL-180 | 22 | 1000 | 1260 | 2320*1600*1150 |

Production line of the charcoal briquette extruder making machine

Use the chaecoal powdee as raw material,the production line as below

Configured cutter:

1.Automatic cutter and conveyor

Control the length of the charcoal briquette by adjusting the distance between the infrared probe and the mold.

Numerical control device, control the length of charcoal briquette by adjusting the number of rollers, the range is 3-40cm

Delivery picture

Company Information

Zhengzhou Shuliy Machinery was found in 2000. Our company specializes mainly produce Recycling and environmentally friendly processing machines, cardboard shredder machine, egg tray making machine, woodworking machines, aerators, toothpicks making machine, feed processing machinery, charcoal processing machinery, and so on. We not only provide customers with cost-effective products but also provide first-class service support and solutions. Shuliy has passed SGS, ISO, TUV, CE, BV, and other certifications. Our products have been exported to countries and regions such as Arabia, India, Russia, Central Asia, Africa, and Mongolia. A perfect after-sales service system allows you to worry-free.

FAQ

Q1: Is the shape replaceable?

A1:Of course. Just change the mold.

Q2:The final size can be adjusted?

A2: Yes,we have two typr cutter,this two typa also can be contorled the final length of the charcoal briquette.We also can provide the conveyor.

Q3:How long can the charcoal burn?A3:The normal time is about 3-4 hours.

CERTIFICATES: