Shisha Hookah Coal Ball Honeycomb BBQ Charcoal Briquette Sawdust Briquette Making Machine

Package size per unit product 210.00cm * 110.00cm * 120.00cm Gross weight per unit product 700.000kg --Introduce Of Shis

Basic Info

| Model NO. | BF-140 |

| Condition | New |

| Warranty | 1 Year |

| After-sales Service | 1 Year |

| Color | Customized |

| Capacity | Customized |

| Raw Material | Wood, Charcoal |

| Final Product | Briquette |

| Transport Package | Wooden Case Packing |

| Trademark | BF |

| Origin | Henan, China |

| Production Capacity | 10000 |

Packaging & Delivery

Package size per unit product 210.00cm * 110.00cm * 120.00cm Gross weight per unit product 700.000kgProduct Description

--Introduce Of Shisha hookah charcoal Coal Coal Ball Honeycomb Charcoal BBQ Briquette Maker Making Machine:

Work process:1. Crushing And Mixing MachineThe machine has both crushing and stirring functions, which greatly saves manpower and improves efficiency.2. Wheel mill(The equipment used for mixing is called a wet mill. Its structure is similar to that of a dry mill, except that there are no sieve holes on the grinding disc, the grinding mass is lighter, and there is a discharge mechanism. Add the batching material and water into the mill, and after kneading evenly, the material is discharged by the unloading mechanism. In the mixing process, it has both stirring and extrusion functions, which can better remove the air between the material particles, so that the mixed mud has a uniform moisture, the surface of the particles is fully wetted, and the mixing effect is good, but it has a certain effect on the particle size of the material. destructive effect. Wet mills are bulkier, have lower output, and have higher energy consumption, but the quality of the mixed mud is good.)3. Charcoal Briquette Extruder with automatic cutter(The rotating impeller sandwiches the raw coal from the feeding port and pushes the coal forward, the raw coal is gradually compressed, and the particles are close together, and at the same time, a relatively large agitation and mixing are generated. At this time, between the raw coal particles, strong friction and shearing are generated between the particles and the blades and the simplifiedcoal rod machinecoal rod machineAt the same time, under the action of heat generation, the temperature of the raw coal rises, the moisture and binder are more uniform, and the plasticity of the coal is also greatly increased. Press into the flat part of the mold, and form the coal rod machine)

1. Crushing And Mixing Machine

| Model | capacity | Power |

| 250 | 800-1000kg per hour | 7.5kw |

| 350 | 1500-2500kg per hour | 11kw |

| 450 | 2500-3000kg per hour | 15kw |

| Model | capacity | power |

| 130 | 500kg per hour | 5.5kw |

| 150 | 800-100kg per hour | 7.5kw |

| 180 | 1500kg per hour | 11kw |

| Model | Capacity | Power |

| 140 | 450-500kg per hour | 11kw |

| 180 | 500-1000kg per hour | 18.5kkw |

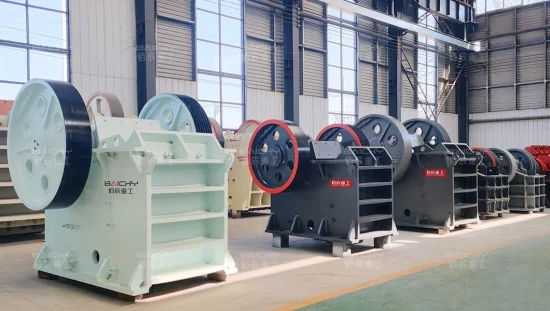

4.Delivery Photos

Send to us